With accuracy down to .002″, DeWys Engineering offers a Reverse Engineering service built to handle your most complicated parts and assemblies.

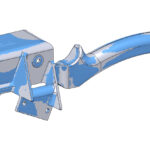

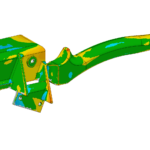

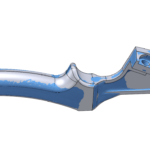

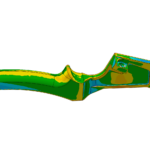

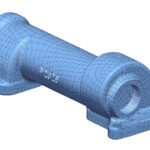

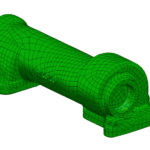

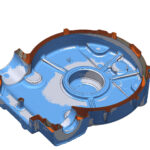

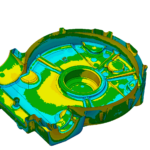

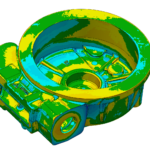

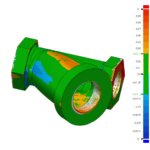

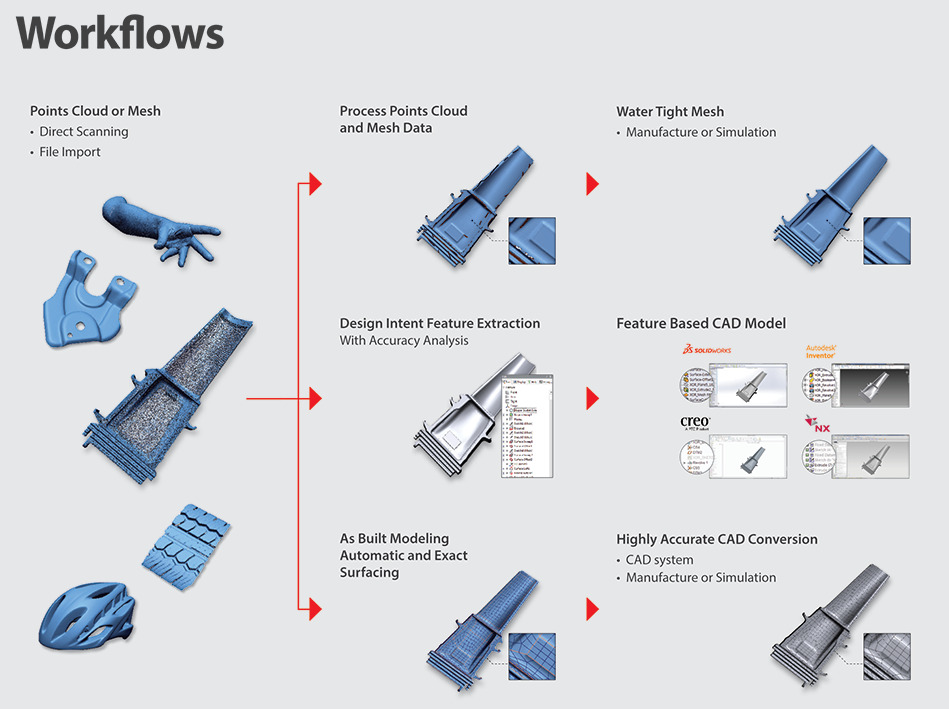

Starting in 2014 DE purchased its first Faro ScanArm to fill a need in the West Michigan area for Reverse Engineering large cast gears and hydraulic components. Overtime the scanning business has expanded its scope to include the 3D laser scanning and reverse engineering of just about everything imaginable. Using Geomagic Design X CAD Software combined with the FARO ScanArm we are able to take digital captures of an object and perform reverse engineering services.

FARO ScanArm – 3D Laser Scanning for Reverse Engineering

Utilizing traditional contact-based part probing at accuracy of+/- .0016” or non-contact 3D laser scanning at +/- .0025”. This 8′ Portable Coordinate Measuring Machine (PCMM) can be taken to any job site for direct measurements within hours of receiving a call or email.

Examples of the Faro Arms capability:

Part to large or too heavy to being it to a traditional CMM or Scanner? No problem, our FARO system will come to your part! It does not matter if the part is in the shop or on the job site, we can scan it.

Other Scanning Technologies

While the Faro ScanArm is a great fit for most laser scanning projects, DE has access to other scanning technologies for the times when jobs necessitate something other then a red line 3d laser scanning. These other technologies include:

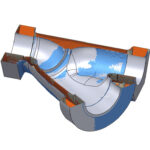

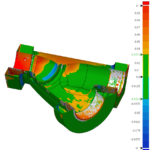

- Industrial CT scanning: CT is well suited for very small parts that are highly detailed or part that require the scanner to look inside them (plastic injection molded parts, assemblies, hollow parts, etc).

- Blue Structured Light Scanning: Blue Light is useful for capturing large parts in extremely high detail as well as capturing color data while scanning.

Lab

DE has a in house metrology lab that is fully temperature controlled and has the ability to accept parts up to 4000 LBS in weight and 10′ x 10′ x 10′ in size. If the part that needs to be scanned is larger or heavier then this, DE has access to high bay manufacturing space directly next to our current lab space with a 10 Ton overhead crane for loading and unloading trucks as well as moving around large parts.

Send us your scan / probe data

DE has several customers who have purchased their own 3D laser scanning or imaging systems who don’t want to deal with training and maintaining a reverse engineer on staff for occasional projects. DE steps into this situation to handle all of their reverse engineering needs. After laser scanning the part they send us the raw scan data files and have us handle the reverse engineering they need completed. This also saves them the cost of maintaining a seat of Design X.

Geomagic DesignX costs around $15,000 per seat plus $3,000 a year in maintenance fees.

To talk about reverse engineering on your project shoot us an email at info@DeWysEng.com or give us a call at (616)604-1977