DE has been working in the foundry industry for years helping clients with Laser Scanning and Reverse Engineering of industrial castings and components. Eventually this led us to help with the reproduction of 3D CAD data for Legacy Castings, sculpture scan, and art pieces used in reproduction and preservation projects. The following are a few examples of Legacy Parts Reverse Engineering jobs we went on to generate the CAD data for. That CAD data was then used to produce new parts that eventually were used in historical theater restorations across the United States.

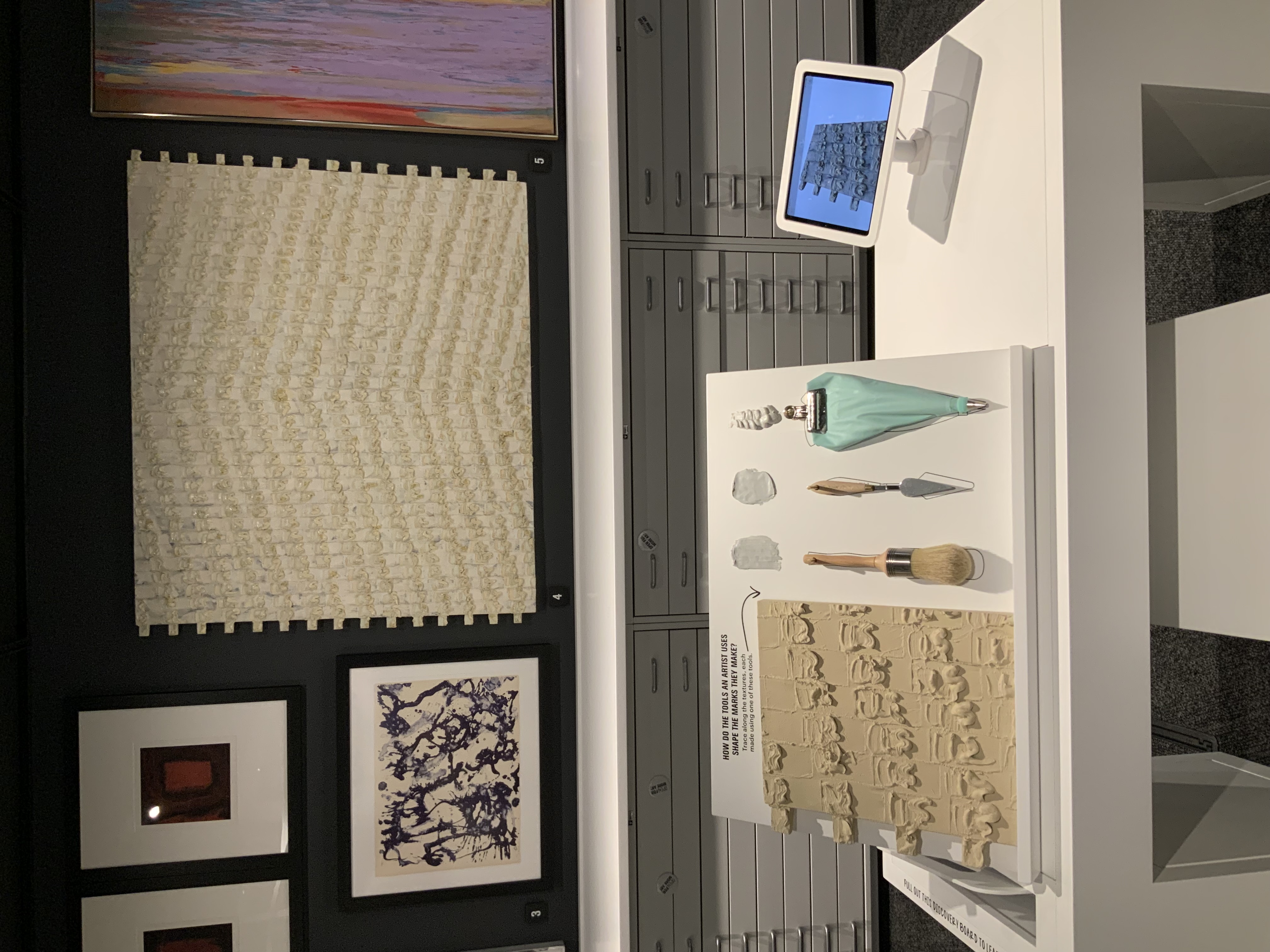

Legacy Parts Reverse Engineering for MSU Broad Art Museum

We received a call from the Eli and Edythe Broad Art Museum at Michigan State University about a project involving Legacy Parts Reverse Engineering. They had 2 parts that they wanted to allow guest to handle without putting the original piece’s at risk of damage. We laser scanned, reverse engineered, and then 3D printed and painted replicas of the pieces in 3 weeks to allow them to open their exhibit on time!

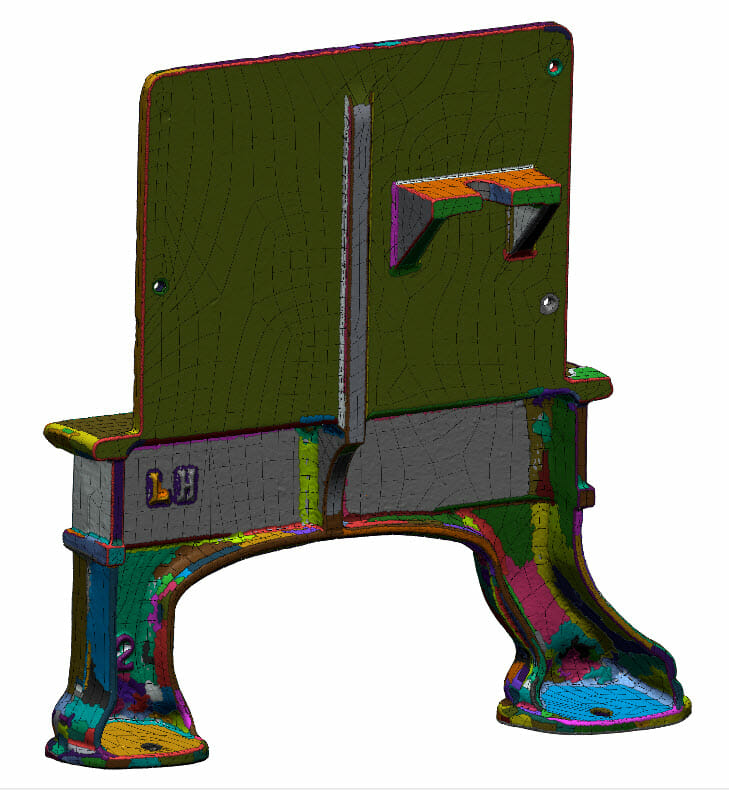

What makes projects like these unique is that they bring together the need to recreate parts with both parametric CAD (drafts, parting lines, holes, chamfers, fillets) as well as organic features in the same part. This causes there to be a requirement for a Reverse Engineer who has the ability to build manufacturable parametric features while still preserving the hand made artist components of the sculpture scan as well. DE has Designers on staff with extensive experience with Legacy Parts Reverse Engineering and using that scan data to produce manufacturable 3D CAD data so new parts can be built.

To talk about Reverse Engineering on your project shoot us an email at info@dewyseng.com or give us a call at (616)604-1977.