Have old tooling that is worn out, damaged, or has reached the end of its life? We can help get you clean, ready to manufacture 3D CAD data using our Tooling Reverse Engineering expertise!

There are many challenges that can happen when it comes time to replace a trusted piece of tooling that your manufacturing operation has depended on to produce good parts. Sometimes it can be a simple as just ordering a new tool to be built, but that is usually not the case:

- The tool could have been built before 3D CAD designs were even around

- It could have had lots of hand work done to it in order to produce good parts

- The 3D CAD data may not be available from the original builder or has been lost over time

The list of potential reasons you may be considering Tooling Reverse Engineering is endless, but we can help!

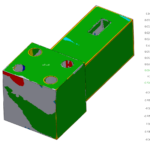

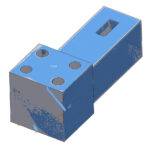

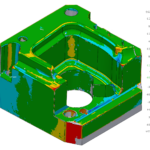

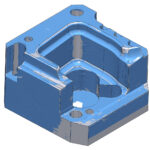

At DE we have been reverse engineering tooling for customers and providing them with manufacturing ready data for years. Some of the types of tooling we have worked on include:

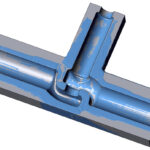

- Stamping Dies: Complete tools and individual details

- Injection Molds

- Compression Tools

- Diecast Molds / Trim Dies

- Specialty tooling for automated manufacturing cells

- Foundry Patterns

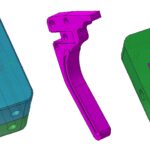

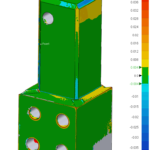

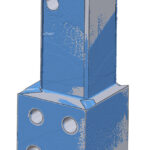

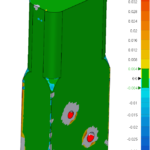

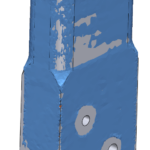

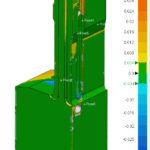

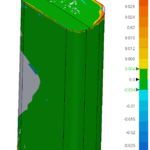

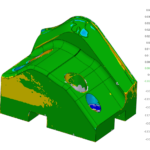

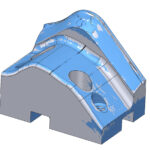

Even if your tool is completely worn out to the point where it will no longer produce good parts that meet spec or if the tool had a crash that damaged or destroyed areas of the tooling surface. We can scan the tool and reverse out things like wear, cracks, chips, erosion, holes, ect. We can also capture things like hand work or polishing that was not present in the original design. Once we have the scanning work done and digitized into our specialized reverse engineering software (Geomagic DesignX) we can draw your tool very accurately and produce 3D CAD data that is ready to be sent to a tool builder or your own maintenance department to have a brand new tool built. We don’t just supply you with an auto-surfaced blob that cant be used for manufacturing, our data is guaranteed to be manufacturing ready!

Want to know more about the tools we use for Tooling Reverse Engineering? Check out our page here.

To talk about reverse engineering on your project shoot us an email at info@DeWysEng.com or give us a call at (616)604-1977