Experts in the design of custom automated machine’s for industries from automotive and aerospace to agricultural and forestry

DeWys Engineering has on staff design engineers with years of practical experience in the design of custom automated machine’s for industries ranging from automotive and aerospace to agricultural and forestry. Our process starts with sitting down with our clients (and in most cases their end customers) to determine the scope of the project and drill down to find the critical features or requirements that the automated system will need to have in order to be successfully integrated into existing processes on the shop floor.

In the event that this is a legacy or take over job for our customer and 3D CAD data on the part is not available. DE has the ability to handle the capture and reverse engineering of our customers part via our in house 3D Laser Scanning capabilities.

Next comes the concept design, DE researches possible solutions that meet the customers requirements and assembles a 3D concept of the machine in CAD that is then reviewed with the customer. After getting feedback the concept is adjusted and then fleshed out in a full design with motions study’s, operator ergonomics, cycle time evaluations, and purchased part vendor meetings . Upon one final review with the customer the design is approved and 2D Prints are completed. This design package is then released to the builder for them to begin manufacturing the custom automated machine.

DE’s involvement does not have to stop after the design is submitted to a builder. Many times we are kept on call to answer questions, handle print redlining, and trouble shoot issues during the build and eventual runoff of the automated system. We also work closely with both in house and outside controls groups usually starting during the concept design phase to ensure that the proper sensor, electric motors, and other items traditionally handled by a controls group are included in the design and properly sized and accounted for on the final 2D prints and bill of materials (BOM).

In the event that you are an OEM who does not have a preferred custom automated machine builder DE has a wide network of excellent partners in this space that we have had long term working relationships with and who would be happy to quote your project. Also, geography is not a barrier to this process, while located in West Michigan, DE has worked with clients all over North America to help bring their custom automated machine’s to life.

Types of equipment we have worked on:

| Material handling for forestry | 3D Printing Post Processing |

| Adhesive application / Robotic | Servo slides |

| Leak testers | Mig Welders |

| End of arm tooling | Alum or Steel Manual weld |

| Loaders / un-loaders | Multi-fastener applicators |

| Aerospace | Packaging equipment |

| Ergonomic assembly tables | Automated inspection |

| Manual Mig-welders | Flying cut off |

| Rotary dial systems | Automated nut runners |

| Fabric wrapping technology | Sonic welders |

| Material handling | Foam in-pace molding / Robotic |

| Bowl fed assembly cells | C Frame presses |

| Plastic part punches | Test stations |

| Heat staking | Pressure tesing |

| CNC holding fixtures | Robotic vision systems |

| Hot plate welding | Hydraulic Presses |

| De-gate equipment |

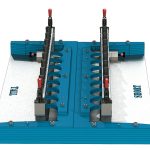

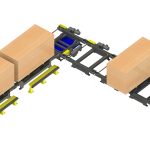

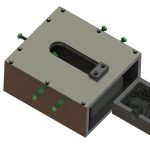

Some Examples of previous projects we have worked on: